Mask is the novel coronavirus’s “protective equipment”. With the resumption of production and rehabilitation in all parts of the country, disposable masks and N95 masks are becoming hottest. Almost all the masks are stolen and sold out everywhere. The price is also up from 6 to 6. Not only that, but also the news of three masks and fake masks has been published.

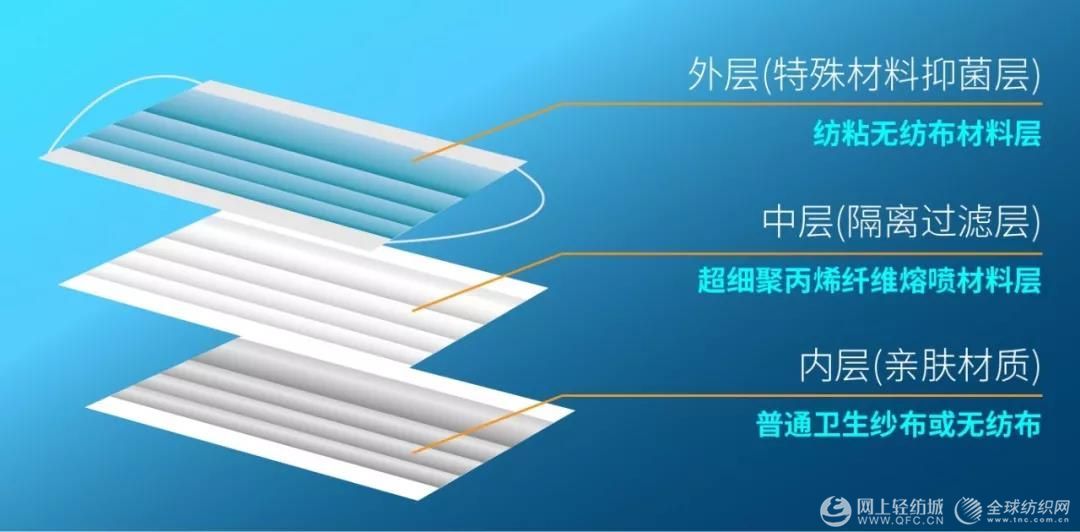

To popularize, medical surgical masks are composed of a mask face and a tension band. The mask body is divided into three layers: inner, middle and outer:

The inner layer is skin friendly material: ordinary sanitary gauze or non-woven fabric, the middle layer is isolation filter layer, the outer layer is special material antibacterial layer: non-woven fabric or ultra-thin polypropylene melt blown material layer.

An ordinary flat mask needs 1g meltblown cloth + 2G spunbonded fabric

A N95 mask needs about 3-4g melt blown fabric + 4G spunbonded fabric

Meltblown cloth is an important material for medical surgical masks and N95 masks, which is called the “heart” of masks.

According to the statistics of China Industrial Textiles Industry Association, spunbonded is the main production process in China’s nonwovens industry. In 2018, the output of spunbonded nonwovens was 2.9712 million tons, accounting for 50% of the total output of nonwovens, mainly used in sanitary materials and other fields; melt blown technology accounted for only 0.9%.

From this calculation, the domestic output of meltblown nonwovens will be 53500 tons / year in 2018. These meltblown fabrics are not only used for masks, but also for environmental protection materials, clothing materials, battery diaphragm materials, wiping materials, etc.

Compared with mask manufacturers, melt blown non-woven fabric manufacturers are not many. Under such circumstances, the state has launched a number of source enterprises to put into operation to improve production capacity. However, in the face of the textile platform and the textile circle where melt blown non-woven fabrics are sought, it is not optimistic at present. China’s production speed in this pneumonia is facing unprecedented challenges!

At present, in the face of the epidemic situation of pneumonia, all parts of the country are increasing production day and night. It is predicted that the mask industry will have the following changes in the future:

1. Mask production will continue to rise

According to the statistics of the Ministry of industry and information technology, China’s maximum production capacity of masks is more than 20 million per day. According to a survey conducted by French domestic radio stations, China is the largest production base of medical masks in the world, accounting for 80% of the world’s production. The government will collect and store the surplus production after the epidemic, and enterprises meeting the standards can organize production with full power. It is expected that the production of masks will continue to rise in the future.

Novel coronavirus pneumonia epidemic prevention and control and economic and social development were held at the press conference of the State Council Information Office on 10 forenoon 24. At the press conference, Cong Liang, member of the Party group of the national development and Reform Commission and secretary general, specially introduced the relevant situation of expanding the production capacity of masks and ensuring the supply of masks.

Cong Liang pointed out that since February 1, the national development and Reform Commission has helped mask manufacturers solve the problems of labor, capital, raw materials, etc., and spare no effort to guarantee the supply of masks. It can be roughly divided into two stages: the first stage is mainly to deal with the epidemic situation and ensure the front-line medical staff, with the focus on expanding the production of medical N95 masks. After efforts, the daily yield of N95 on February 22 has reached 919000, which is 8.6 times of that on February 1. Since February, through the unified operation of the state, 3 million 300 thousand masks have been dispatched from the N95 masks producing provinces, focusing on the protection of Wuhan in Hubei, and Beijing and other areas without N95 production capacity, including 2 million 680 thousand medical N95 masks transferred to Wuhan, and the daily dispatching volume is also more than 150 thousand.

2. Professional masks will gradually occupy the market

With the continuous development of China’s economy and the continuous improvement of people’s living standards, people’s consumption concept and consumption level have also changed and improved greatly. In recent years, with the increasing emphasis on personal safety protection and the incidence rate of occupation diseases such as pneumoconiosis, the market of professional masks is huge.

In the future, professional masks will continue to occupy the market, while the market share of low-end full gauze masks will continue to decrease, which is an inevitable trend.

Therefore, at present, it is still relatively profitable to make masks in factories. Many factories have reformed to make masks. It depends on who can seize the business opportunities.

China is the world’s largest producer and exporter of masks, and the annual output of masks accounts for about 50% of the world. According to the data released by China Textile Business Association, in 2018, China’s production of masks will be about 4.54 billion, which will exceed 5 billion in 2019 and will exceed 6 billion by 2020.

Post time: Oct-17-2020